Why the Fashion Industry Needs Standardisation

by Coats Digital

Speaking the same language to secure a better, more sustainable future for all stakeholders

How one proven, scientific standard could be the key to sustainable creation, collaboration, and compliance.

Key Takeaways:

- To clear the high bars necessary for supply chain visibility, due diligence and disclosure, and regulatory compliance, fashion should look to scientifically validated metrics like Standard Minute Values (SMV) as the building blocks of transparency.

- Those building blocks can then be translated, using brand-facing tools like GSDCost, into greater collaboration and accountability.

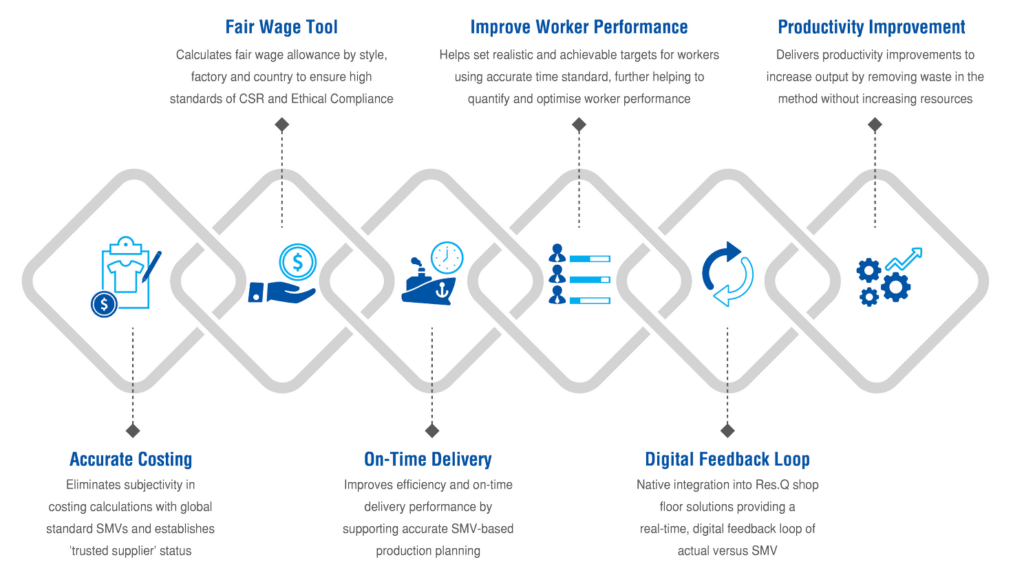

- Coats Digital’s GSDCost platform aims to help brands predict costs, negotiate effectively, establish visibility into key metrics like fair wages, and build more ethical and more resilient supply chains.

Fashion industry disruption is here to stay

Despite it still being the first half of the year, fashion has already experienced its fair share of turbulence. As brands and retailers continue to grapple with extended disruptions in their supply chains, and as shipping companies continue to divert around the Suez Canal to avoid conflict, it’s becoming clear that 2024 did not start from a position of upstream stability in a pure logistical sense.

This is being compounded by the difficulties brands (and by extension consumers) continue to have in mapping and understanding their deeper supply chain relationships and purchasing practices – from raw materials to procurement and production partnerships. As the findings from the recent 2023/24 supply chain and sourcing survey revealed, 67% of brand and retail businesses have either “fair” or “lacking” visibility into what they consider to be key supply chain metrics, and this is having a pronounced impact on the industry’s ability to measure and manage its efficiency and its extended footprint.

Contrast this with the growing demand for data capture and disclosure across the environmental and humanitarian elements of those supply chains, and it’s similarly clear that 2024 will continue the trend towards fashion businesses needing to build and maintain robust records of where their products are made, from what materials, and – critically – by whom, and for what compensation. Across a broad spectrum of datapoints, brands and their partners can no longer rely on approximation, averaging, and intuition – data rules the roost.

As a case in point: around this time last year, the Corporate Sustainability Reporting Directive (CSRD) entered into force. The directive refreshes and strengthens the rules concerning the social and environmental information that companies have to report on, and now a broader set of companies – from the large enterprise to the SME – are either already being required to report on both the environmental and ethical sides of sustainability, or will soon be required to make these disclosures. The first companies will have to apply the new rules for the first time in the 2024 financial year, for reports to be published in 2025 – giving the fashion industry little time to comply. Not yet in effect, but soon to be, is the similarly-named but differently-scoped corporate sustainability due diligence directive (CSDDD), which focuses on making businesses even more accountable for the social and environmental impacts of their operations, and enforces a baseline standard for due diligence and reporting.

But crucially, while the impact of this kind of legislation, along with that pervasive disruption and lack of visibility, is often talked about as being primarily a brand and retail issue, suppliers and manufacturers across the multi-tier supply chain are also feeling the pressure. They face a lack of standardisation in requests for information, historic scrutiny of their operations by brands, inspectors, legislators and consumers, and a competitive environment where their brand customers are cross-shopping more than ever to safeguard themselves against disruption and risk, and to chase better margins.

Against that backdrop, both suppliers and manufacturers need reliable ways of securing their own business continuity, mitigating that risk, and securing their competitive position across capabilities, cost, sustainability, speed, and other key metrics – at the same time as complying with a tightening window of regulations. In 2024, then, it will not just be brands, but the wider industry – encompassing every stakeholder – that will need higher levels of agility, visibility, and efficiency than ever to remain on a stable footing in a time of ongoing unpredictability.

And this makes the search for standardisation, proven data, and a new foundation for negotiation and collaboration one of the industry’s most pressing challenges – especially as it relates to the structures within which garment workers are paid.

The importance of standardisation and data sharing

For brands, finding that kind of agility typically means a shift in sourcing strategy.

To remain competitive, compliant, and conscious of environment and ethics, brands and retailers need creative, on-cost products in the market quickly, with full visibility into their provenance and their impact on the planet and people. To hit as many of these targets as possible, brands are aiming to both diversify and deepen their supply chain relationships – finding new partners and redefining the ways they work with existing ones.

And to shoulder the burdens being passed on to them as a result of those targets, suppliers are seeking to build their own efficiencies, protect their own margins, and to trade with their customers based on accurate, standardised data.

Across both audiences, the new mandate is therefore building the ability to easily compare orders and contracts between different vendors and customers, with the confidence that one can be contrasted with another like-for-like, as a way of fuelling intelligent decisions.

And with the right data foundations, those decisions can be modelled, tested, and honed in advance – taking negotiations beyond pure cost comparisons, and examining the suitability of different production environments, machinery logistics setups and other variables.

Those same data foundations will also be critical for both parties’ ability to diversify their operations – whether it’s spreading their sourcing bases wider, in the case of brands, or taking on more widespread, less consolidated customers in the case of suppliers.

To meet that demand for standardisation and mutual understanding, what fashion needs is, essentially, an equivalent of the tools that allow consumer markets to cross-shop, to develop and refine their offers with suppliers, and to directly compare one proposition against another based on a wide spectrum of different indicators – from cost to impact.

From the perspective of sustainable sourcing, accurate costing, and fair labour standardisation in fashion, this isn’t wishful thinking: the concept of a standard minute value (SMV), as the essential building block for accurate, sustainable costing and worker compensation has provided exactly this framework for a long time.

To use its scientific definition, an SMV – as per the definition in the ILO Introduction to Work Study – is the “time value arrived at for a task based on the average rate of output which qualified workers will naturally achieve without over exertion provided that they know and adhere to the specified method and provided that they are motivated to apply themselves to their work.” Or, in other words, a system of rigorous, scientific standardisation for the work that partners in sourcing and manufacturing put into bringing a product to market.

Despite the label “scientific” a properly calculated and systematised SMV is anything but cold and distant: it incorporates allowances for various factors such as rest, machine delays, and anticipated contingencies, making it a comprehensive measurement of time that also takes account of the fact that that time is being bought and provided by human beings.

So when we think about establishing a new data foundation, we should, as an industry, be thinking about making more effective use of a tool that already exists – and one that has been successfully deployed in the supply chain, and had solutions successfully built on top of it, by industry giants like Coats Digital. The accuracy and consistency of a framework built on independent, objective, humanised SMVs can serve as the foundation for organising key business processes (including production targets, line balancing, production planning, incentive schemes, and the assessment of operator performance and factory efficiency) at the same time as giving brands and suppliers the mutual building blocks of sustainable sourcing, accurate costing, and data-backed collaboration and accountability.

But it’s crucial to understand the difference between your own in-house SMVs (or SAMs as they might be labelled) which are likely to have been built up over time through averaging, homegrown calculations, subjective negotiation, and broad-brush regionalised labour costing.

A spreadsheet built by a single brand and updated sporadically over time – even if it began with the best of intentions, and data that was, at some point, historically correct – is not functionally equivalent to a true labour quantification and costing solution. And between those two approaches, only one is likely to stand up to disruption, uncertainty, regulation, and consumer scrutiny in the very near future.

The standardisation solutions

Built on top of General Sewing Data (GSD), which has become the global standard in time-cost and method analysis, GSDCost from Coats Digital has developed new functionality in its scientifically-based solution, enabling brands to collaborate more effectively and meaningfully with vendor partners and support more sustainable and responsible growth across the fashion supply chain.

The new capabilities available in GSDCost allows brands to use the power of scientifically-backed international standard time benchmarks based on accurate SMVs to create credible Bill of Labour (BOL) garment style requests, issue these to multiple vendors at the same time, and compare and contrast the various Cost-to-Make (CM) responses quickly from one platform.

The use of a scientific, common language and standards supports accurate cost prediction, fact-based negotiation, and a more efficient garment manufacturing process, while concurrently delivering on CSR commitments.These foundations can provide clear sustainability benchmarks and frameworks for improvement, to support a wider drive into on-demand manufacturing and domestic production that can be contrasted against offshore, traditional methods using a scientific, like-for-like standard.

Coats Digital developed the solution after having taken careful consideration of feedback from brand customers regarding the challenges around effective and meaningful collaboration with suppliers whilst securing more accurate CM quotes based on a standardised set of criteria. The unique, brand-focused features in GSDCost is a major step towards brands being able to create, collaborate and compare credible BOL estimates using the same language and means of assessment for all vendors across their value supply chains. Brands will now be able to drill down into specific BOL discrepancies between vendors, factoring in whether one vendor has perhaps more advanced machinery or increased automation, for example, or another has more expensive, but better sustainability and fairer wage practices. This will also significantly help brands quickly ascertain which vendors fall short of new global compliance rules and which suppliers they would like to work more closely with.

In the current moment of volatility and heightening compliance around sustainability and fair wages in the fashion industry, doing this has never been more important for brands and retailers. Coats Digital’s new, powerful tool – that is backed by the Fair Wage Network and the International Labour Organisation (ILO) – will play an essential part in helping brands to establish a much more transparent and collaborative relationship with all their supply partners, while also rising to address the new industry compliance requirements.

The foundation of a better fashion industry

So much of what the fashion industry wants to do, in a strategic sense and from the perspective of compliance, rests on the idea of finding or building a new, common foundation for costing, sourcing, production, and impact measurement across human and planetary boundaries. But framing this as a search for something new is unnecessary, since – at least from the perspective of fair labour, accurate costing, and new methods of brand-supplier collaboration, that foundation already exists, and has been stress-tested in its pure data form for years.

Now, as a brand-new usability, collaboration, and integration solution layer built on top of it, GSDCost could be set to steer fashion companies towards the right path of resilience, stability and success.

This article originally appeared on The Interline website.

Adopting a sustainable fashion strategy to combat labour cost inflation

All Blog Categories

- Method Time Cost Optimisation

- Supply Chain Solutions

- Sustainability

- Corporate

- Design and Develop

- Fabric Optimisation

- Production Planning

- Shop floor execution

- Videos